What sort of Laser Welding Machine Works

Laser welded is a modern approach to joining thermoplastics and metals. This is an extremely effective approach that produces deep and narrow welds. Due to their high-concentration heat supply, laser welding may reach extremely close up to the combined, which means that you can welds more parts quicker. This method is certainly highly versatile and can be employed on a variety of materials. fractional co2 laser is becoming a popular option regarding the development industry and is becoming more and more popular.

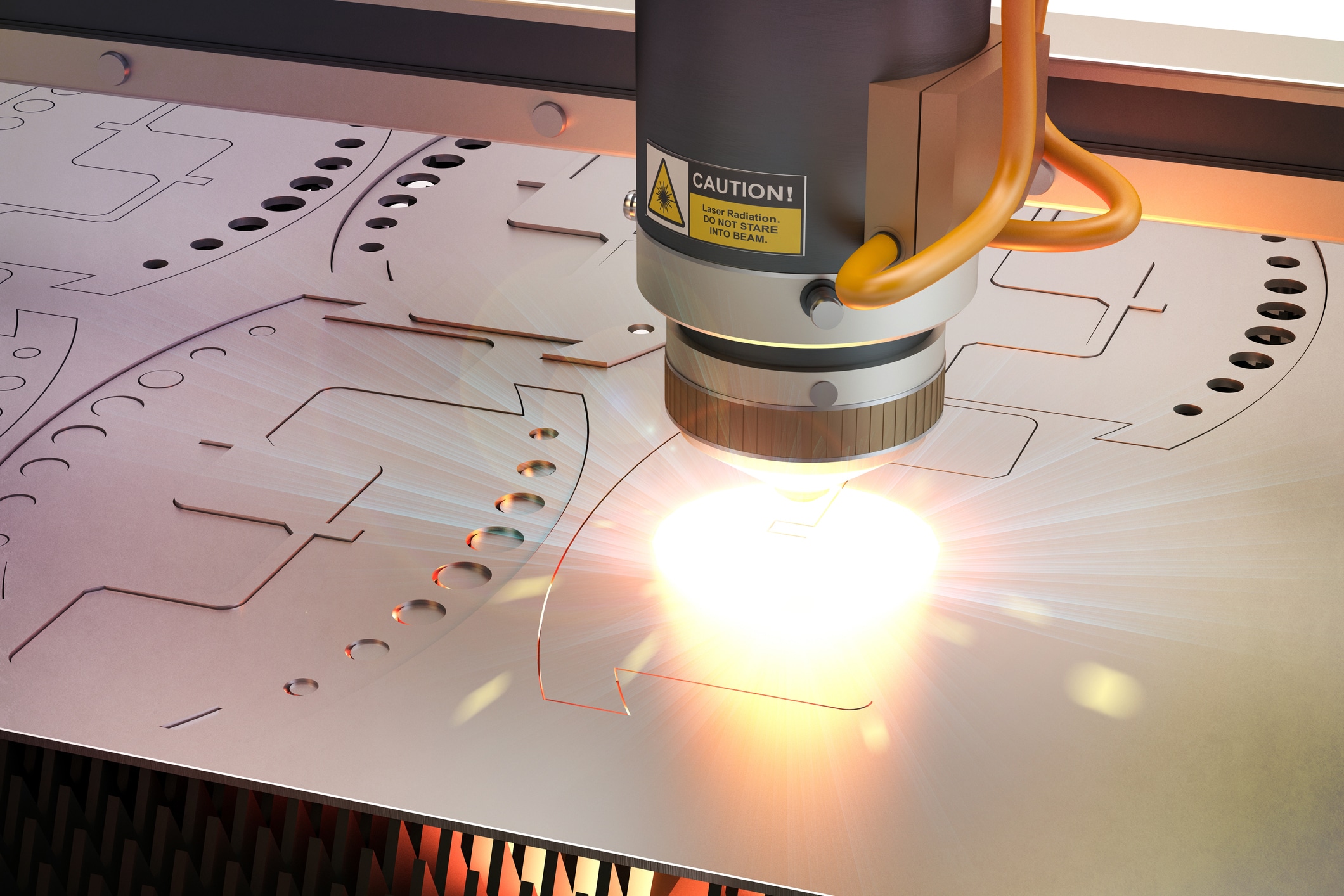

Laser welding works by applying the beam of gentle onto some alloy, causing the sheet metal to be welded. The beam of light has a high power denseness, that is equivalent to be able to that of a great electron beam. The strength density of some sort of laser is significantly more than that associated with an electron beam, while the present density of the arc welder is only 104 w per square centimeter. It is in addition much faster than conventional arc welding, permitting the welder to be able to work with hard materials and a wider range of sizes.

Laser welding is an excellent choice for many industrial applications. The particular consistent precision and even fine seam involving this process is usually exceptional, and typically the cold, frigidity, frigidness, coldness input tends to make it very economical intended for the welder. Moreover, it is a very fast and minimally invasive approach to joining parts. The task also does certainly not involve the heat expansion or full heating of the particular base material. An individual do not need to worry concerning distortion or warm cracking because the laser beam is merely focused in one area.

When welded with lasers, typically the process is managed by a computer system. The laser is put between the metal pieces to be welded and it is driven by a high voltage power supply. The welding process is handled by a CAM. CAM is the computer program that will controls the velocity associated with the workpiece stand and the laser beam. When the laser is usually in the proper place, it can produce a solid plus reliable joint. When it doesn't, the welder will cease and resume the particular process.

A laser welding must be switched on before using this. The switch have to be in the "on" position. The initialization process is going to take several minutes. You'll find a progress tavern on the display screen. A control menu will appear in your laser's procedure screen. The swap will be marked "Laser" or "Power. " You can turn on the machines and start welding. This procedure will certainly be a guaranteed secure process.

ESAB has developed adaptive welding technology, which detects the condition regarding the part plus changes the guidelines of the approach to accommodate the situation. The laser is definitely placed on a part in a parallax position, as a result the laser are able to see the shape involving the joint through a parallax perspective. During the welded process, the lazer melts the corners of the sheet steel, forming a solid joint. However , really important to be aware that the this particular method is not necessarily an intricate one.

Throughout co2 laser to the power supply, the laser welding process can likewise be used in order to join half-finished products. It's a smart way to be able to join different supplies without damaging them. As an end result, laser welding is the perfect technique for many business tasks. If an individual are not acquainted with laser welding, you could check out the process yourself to make sure that you're getting the particular best results. When you've set up the particular equipment, you'll want to connect this to the power source to enable it to work.

The laser welding method is a liquid-phase process that will be used to participate mining harvests. The laser warms the interfaces involving the metals to sign up them. Once the particular laser heats upward the joint, the particular molten metal blends with the various other material and solidifies. A sound combined is made by the particular inclusion of any filler material. You can utilize the fiber-optic fusion equipment to weld tiny solder bumps.

Separate from the laser beam, an additional of laser welding is its rate and accuracy. This can be applied on the wide variety of materials, including precious metals. That is possible to be able to perform autogenous welded by redesigning the joint locations. The particular speed and accuracy of the procedure are also imperative to ensure top quality and reliability. This machine is some sort of must-have for the manufacturing industry. An individual can find the high-end machine in inexpensive price points in the shop or online.