Tungsten Carbide Ball and Rod Properties

Should you be interested in the particular properties of the tungsten carbide ball, you've arrived at the right place. In this article you'll find info about the properties of tungsten carbide and how that compares to other alloys. This article also contains information about the solidity of tungsten carbide rods.

tungsten carbide

Tungsten carbide balls bring many applications, such as linear bearings, machining, and other tasks that require large hardness and have on resistance. These particular materials is designed for intense temperatures and usure, making them the superior substitute for classic steel balls. These kinds of specialized balls can last a lifetime, even with intense usage.

Tungsten carbide golf balls are available in a large variety of dimensions and materials. That they can be found in bearings, valves, movement meters, ball anchoring screws, and other software. Tungsten carbide tennis balls may also be custom manufactured for specific apps. The fabric is also deterioration . and abrasion-resistant, making them suitable for a new variety of professional and commercial apps.

Tungsten carbide is usually one of the hardest metals known. Its high firmness and wear level of resistance can make it ideal for coining, pivots, detents, and other precision-engineering applications. It also is an useful stuff for tracers and even gauge tips. While most tungsten carbide balls never avoid corrosion, carbides produced from more proof binder materials are around for use in corrosive environments. For individuals applications requiring substantial levels of corrosion-resistance, tungsten carbide level 5 and level 3 are accessible.

tungsten carbide ball

A tungsten carbide ball is a high-performance abrasion, arctic, and corrosion-resistant soccer ball that is suited to industrial and professional applications. These tennis balls can be employed for cutting, shearing, tempering, and quenching. They are furthermore suited to use in heavy machinery and even drills.

black tungsten carbide are made from totally virgin tungsten carbide and are tremendously long lasting. They are 3 times harder as compared to steel. Tungsten carbide balls are widely-used within many applications, which include steel bearings, musical instruments, machinery, and professional medical equipment. They could resist heat and wear better than steel balls.

Tungsten carbide is slightly magnetic. For this reason, that they can be selected up with a magnet. A tungsten carbide ball includes a thickness of. 54 pounds per cubic inches. It is likewise stiff and has a Young's modulus of 98, 1000, 000 pounds for each square inch.

The production of a tungsten carbide soccer ball begins with a new process generally known as pre-sintering. The tungsten carbide powder is combined with carbon natural powder in a carbon crucible, held with a temperature by a great arc of electrical power. The mass is usually then milled to be able to a fine powder snow and screened to obtain an uniform particle size.

hardness regarding tungsten carbide

Tungsten carbide balls are really hard and dimensionally solid. This makes them suitable intended for many applications that will require high numbers of hardness and wear resistance. Tungsten carbide balls are particularly within inertial routing systems and high-load bearings. melting point of tungsten carbide can withstand incredible heat and pounds and are remarkably resistant to tough shocks. Typically, a new tungsten carbide basketball is 3 occasions harder than metal.

Tungsten carbide balls are commonly used for a variety of applications, including inside high-precision instrumentation, striking and grinding experiments. Additionally, tungsten carbide balls are used throughout the steel and even foundry industries. Thereby, they are a great substitute for material in many applications.

Tungsten carbide is really a dense material with a high Young's modulus. It has nearly twice the strength of steel, letting it withstand high temps without breaking. One more advantage is its low thermal development coefficient, which makes it an ideal raw stuff for cutting tools. Tungsten carbide is yet a highly stable stuff that will not oxidize at standard air temperatures.

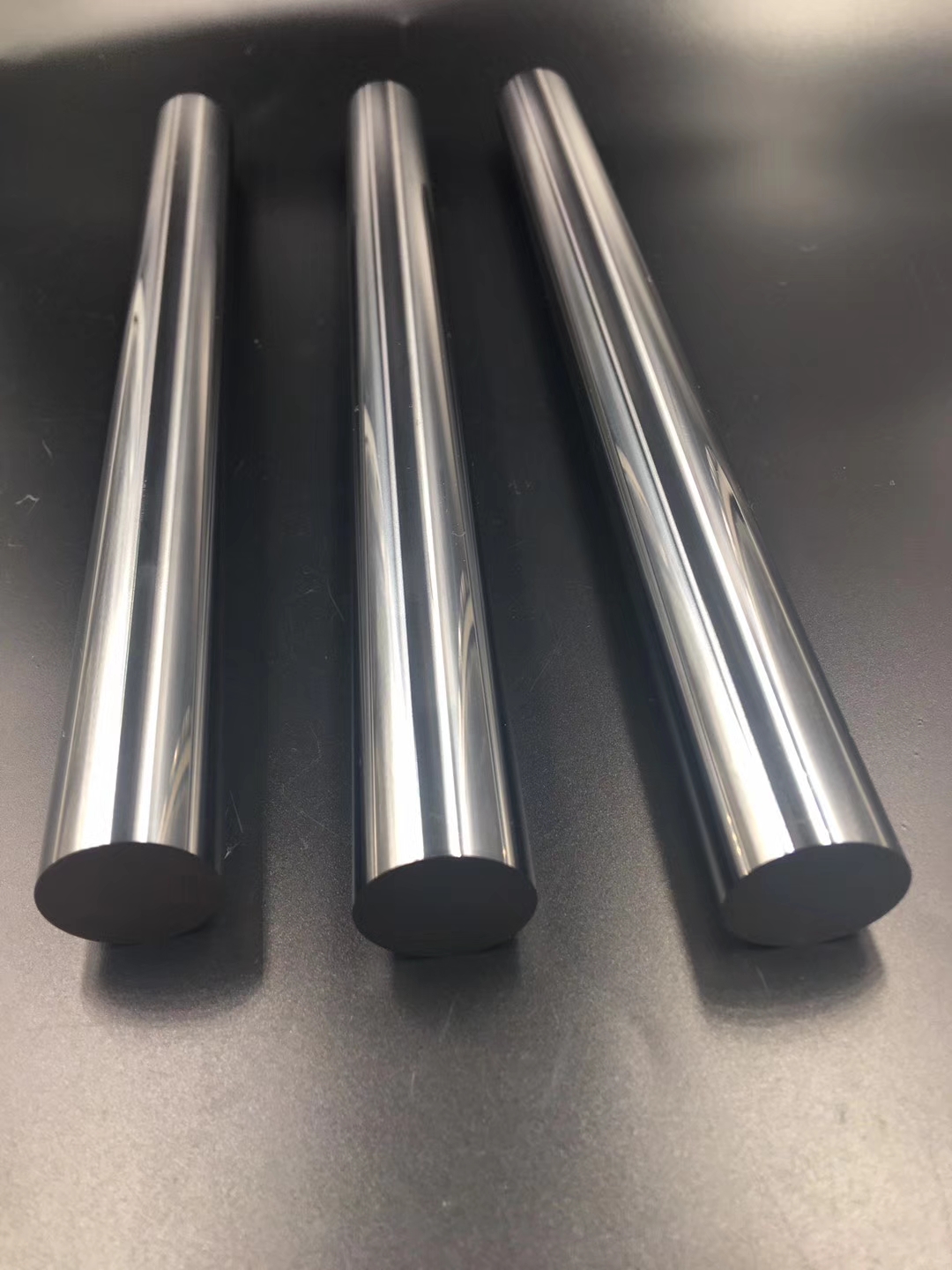

tungsten carbide fly fishing rod

Along with the advancement regarding science and technologies, the demand intended for tungsten carbide equipment is on typically the rise. The manufacturing process of tungsten carbide rods entails many different steps. A single of the almost all important steps is usually called extrusion. In the course of this process, some sort of dried mixture will be poured into the mixer and the material is regularly rolled and stirred over a specified time period. Following about 2. a few to 3 hours of rolling milling, the particular plasticized mixture is usually discharged as standard spheres.

Another advantage of using some sort of carbide rod is definitely its cost performance. It can be purchased with a low cost in comparison to other supplies, which makes that a great investment regarding most users. It is also solid and contains high opposition to cracking and wear. Its corner life is extremely long, which tends to make it an superb choice for all those who want in order to avoid frequent instrument purchases. However, that is important in order to ensure that the class of the carbide rod you get is the appropriate one particular for the application you are going to be using it with regard to.

The global corroborate carbide rod (Tungsten carbide rod) companies are divided into various segments based upon application. The report covers key regional and global market data, like the production capacity, value, plus growth rate associated with the various sections.