Laserlight Cutting Machines - Benefits of Metal Engraving and Laser Cutting

If you're looking for some sort of laser cutting equipment, you've come to be able to the right location. This article will certainly discuss the benefits of metal engraving and laser slicing as well since some of the best machines available. Investing in a metal engraving machine may help you create high-quality designs on the variety of distinct materials. The benefits of metal engraving in addition to cutting will aid you create the products you've constantly dreamed of. But how would you choose the particular right one?

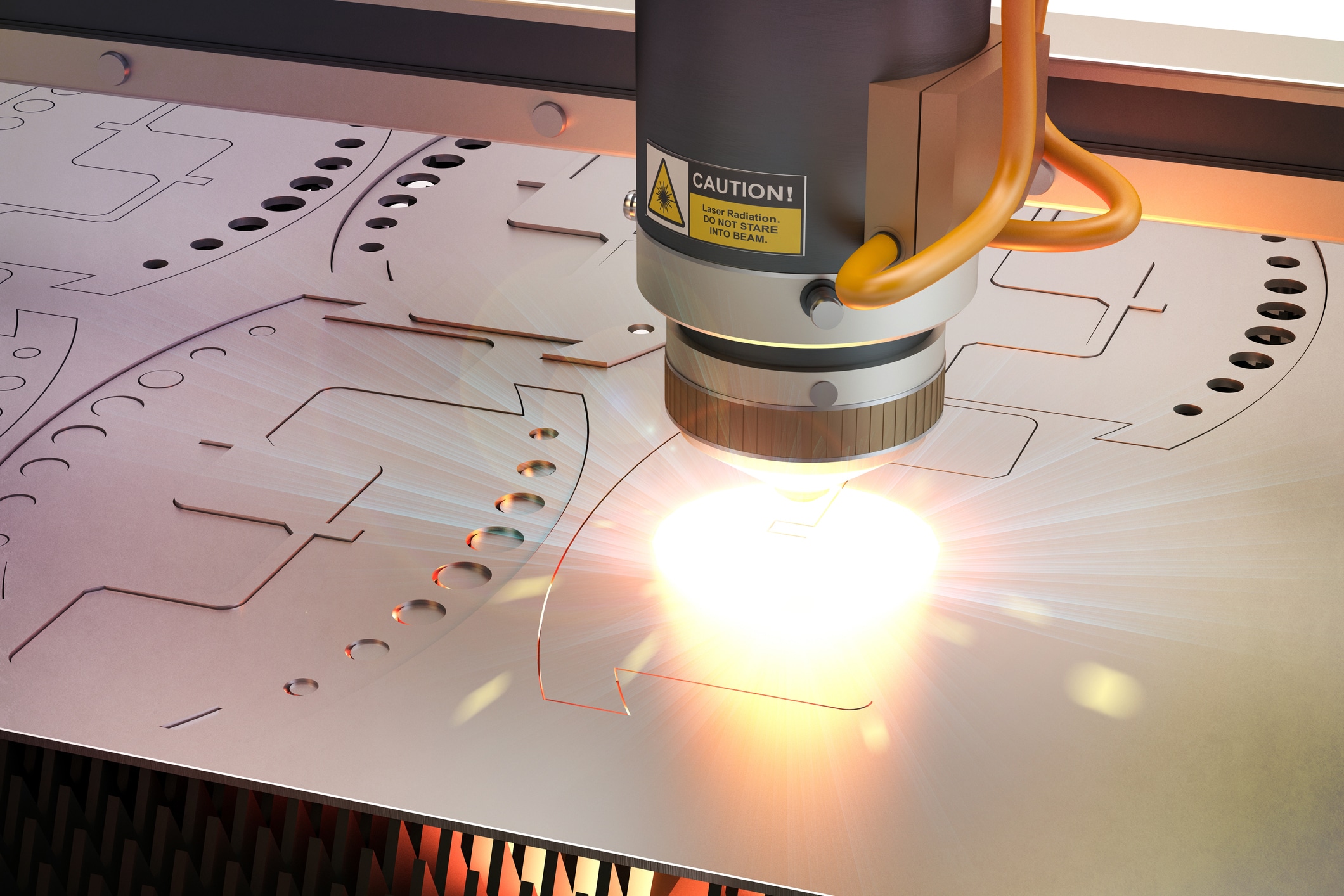

laser cutting machine

A laser cutting machine is an instrument that uses the laser beam to cut flat materials. The beam is generated through an electric powered discharge or diode and is focused upon a material. Typically the laserlight is then shown from strategically put mirrors, transforming that in a cutting laserlight. This laser beam passes by way of a nozzle of compressed smells to cut the material. Using a laser beam cutting machine is the perfect option for many cutting applications.

However, not all materials can end up being cut with the laser. Polyvinyl chloride emits toxic gases and acids. Polycarbonate can be slice but it can easily result in spots of discolouration. This is because it absorbs infrared light, which prospects to inefficient reducing. A laser cutting machine should possess an air conditioning that prevents overheating and stops the laser any time doors are opened up. Its USB port allows users in order to upload designs through their computer.

laser cutting

A laserlight cutting machine functions by focusing some sort of beam of extremely focused light upon the material in order to be cut. In the past, the particular beam was focused through mirrors, although today, the laser treatment are focused employing fiber optics. The particular beam of light-weight can melt, burn off or vaporize some sort of material, depending on the type associated with laser used. This kind of article outlines just how the machine runs and what you need to realize to help make the most successful use of one particular.

A good laserlight cutter will also have an expert training system due to its users. There are bound to be difficulties with the device although it is within use, and the particular manufacturer has to be ready to address individuals dilemmas promptly. After-sales services includes consultation, estimate, and process examination. Other services consist of production, quality command, shipping, and custom made clearance. Getting technical support from the maker might be a great benefit when you have a particular problem or concern after getting a machine.

metal engraving

The first step to be able to finding the appropriate laser cutting machine for your requirements is determining the fabric you want in order to cut. During your stay on island are a lot of different types associated with laser cutters, you will almost certainly need to have to buy a single that will manage your own chosen material. Listed below are some of typically the most common varieties of material to minimize with lasers. These materials include wooden, bamboo, ceramics, household leather, rubber, and actually fruit peels in addition to cores. Moreover, some machines can cut non-woven fabrics and report cards. Also, they are made to be portable and feature wireless Bluetooth connectivity.

The particular laser cutting procedure is simple to recognize and can become joined with marking plus engraving. First, you should ensure the particular size of the particular laser platform is usually large enough for the largest components of material. Then, make sure this has Class 4-capability. For laser cleaning , choose a laser that utilizes a wavelength of 1. summer microns or larger. co2 laser is definitely absorbed by just about all metals, and 10. 6 microns ideal indirect marking.

laser beam engraving machine

There are several factors to look at when buying a laser beam engraving machine. Cost and volume of production are important components when selecting the right machine. Type associated with laser, wattage, and even working area all may play a role in device cost and functionality. Different types associated with laser engravers have different functions and features. Since a rule of thumb, the higher the wattage in addition to work area, the more expensive the equipment will probably be. A laserlight engraving machine's functions, functionality, and cost will determine its overall cost.

Typically the accuracy of some sort of laser engraver's graphic is an important factor to think about when picking out an equipment. This measurement indicates the acceptable mistake range for lazer engraving. Accuracy is dependent on the pixel density, the optical system technology, plus thermal control technologies. Accuracy also may differ depending on the quality of typically the components. Poor quality elements will affect engraving accuracy. It's select a machine that has an accurate setting tolerance.